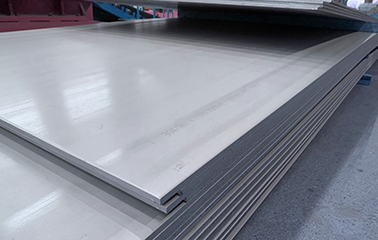

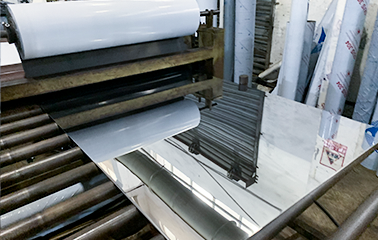

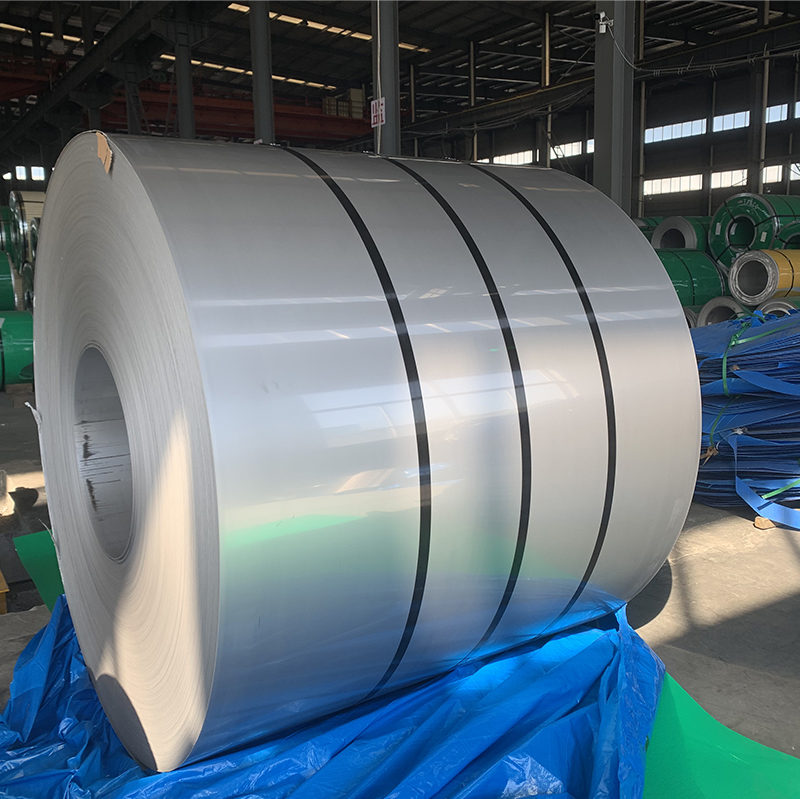

Matte finish

Matte finishes are dull in appearance and are not ideal for aesthetic end uses. However, they’re a good choice where appearance is not important or when further finishing is intended.

The finish is produced by ‘cold rolling’ stainless steel through special rolls or dies. The cold rolling produces a smoother, less pitted surface. Next it is softened and de-scaled in acid solution. The steel is given a final pass on polished rolls to further enhance its smoothness.

Common applications include:

Chemical plant equipment

Pharmaceutical equipment

Paper mill equipment

Laundry and dry cleaning

Refrigeration

Sewage equipment

English

>

English

>

Russian

Russian

Spanish

Spanish