Why Choose Laser Cutting?

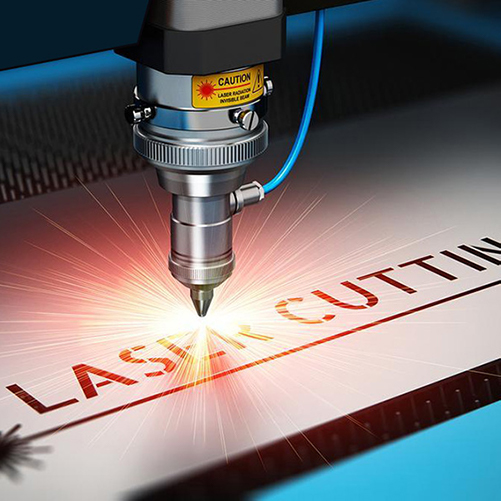

HUACI metals offers a variety of products produced using different methods and technologies. Our laser production process results in highly refined stainless steel components that are appropriate for use in a variety of industries. The process is our most popular due to its efficiency and the limitless capabilities.

The profiles can have varying degrees of thicknesses and are available in different grades of materials fused into one section. Another advantage is that laser cut and fused profiles tend to have better surface finishes. Our laser fused sections go through a stringent quality control process to ensure the precision and clean lines of the finished products.

Please contact us to find out more about our worldwide services, including our laser cutting technology and the profiles that are available.

Benefits of Laser Cut Stainless Steels in Specific Industries

Nuclear Power Industry

Back in the 1970s and 1980s, carbon steel was the typical material for constructing nuclear power plants. Today, many of these plants need reparations with less corrosive materials. Therefore, many carbon structures are being repaired or replaced with 316/L laser fused stainless steel. One of our largest projects was repairing a South Florida nuclear power plant that was susceptible to corrosion from the humid saltwater climate.

The Marine Industry

Stainless steel is a perfect match for the marine industry where corrosion resistance is imperative, especially in the manufacturing of lift and boarding equipment for large and small sea crafts. The construction of nautical cranes for example need materials that can withstand the detrimental exposure to saltwater, humidity, and temperature differentials. Duplex stainless steel offers a higher yield strength and better corrosion resistance than other stainless steels. So our custom laser fused profiles made of duplex stainless steel fit the bill for the marine industry.

Architecturally Exposed Structural Steel

It is no secret that architects and engineers are enamored with the beauty and efficiency of using Architecturally Exposed Structural Steel (AESS). Stainless steel is the product of choice due to its corrosion resistance, refined surface finishes, workability, strength, hygienic qualities, and low maintenance. Laser fused shapes and profiles are of particular interest to designers because of the clean lines and nearly invisible welds. Designers, including artists, really appreciate the aesthetics and durability of the material.

English

>

English

>

Russian

Russian

Spanish

Spanish