Punching Plate Product Details

| Product |

Punching Plate |

| Material |

316L 430,201,304,310,316 |

| Advantage |

Fast delivery, wholesale price,wide range of colors |

| Thickness |

0.4-1.5 mm |

| Width Range |

50mm-2000mm or customize |

| Original |

TISCO, BAOSTEEL,JISCO,ZPSCO |

| Other Service |

Color coating,cutting,slitting,bending,process as drawing workable |

| Standard |

AISI,GB,ASTM,ASME,EN,BS,DIN,JIS |

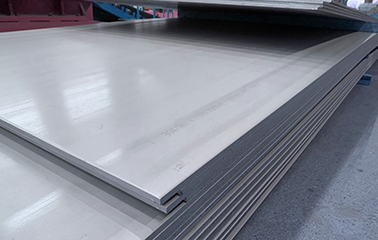

| Surface |

Wiredrawing, mirror, 8K mirror, color coating, etching, anti fingerprint, water mark, perforation, grid |

| Sample |

Samples can be provided for free. |

| Application |

Building applications,telephone booth,kitchen appliances etc |

Introduction of Punching Plate

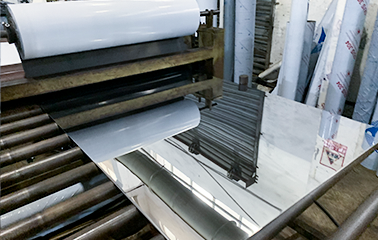

The most common method of piercing is punching. We are able to supply your plates exactly according to your requirements. This can be blank areas, different angles, square perforations or slots.

Our sheets are available in thicknesses ranging from 0.3 to 20 mm in steel. For stainless steel this is 15mm. Standard board size is 2000 x 1000mm. However, we can supply plates up to 6000 x 2000 mm. After stamping, the sheet is straightened and degreased to remove residues used in the machining process.

For example, available alloys are Steel, Stainless Steel, Inconel™, Incoloy™, Monel™, Duplex™, Titanium, Copper and Brass.

Advantages Of Perforated Plates

1) Aesthetics

Perforated metal offers a unique modern rhythm aesthetic that complements any building. With an almost endless selection of hole shapes, sizes, geometric patterns and finishes, perforated metal makes it the perfect material to achieve a specific look. In addition to adding visual interest to the exterior of the building, the perforated metal allows occupants to enjoy the exterior views while maintaining a degree of privacy. Perforated metal provides comfortable natural lighting during the day, reducing the amount of artificial light required while deflecting heat.

2) Versatility

Perforated metal materials are widely used. Easily bent and configured according to your design, it can be used as a lightweight decorative element or as a structural part in a building. The structural advantages of perforated metal offer architects and designers a variety of options to explore. Examples of creative uses of perforated metal include sunscreens that filter and control light; balustrade fillers that add structure while reducing mass; column covers that enhance aesthetics and offer many design options...and more.

3) Durability

Perforated metal has structural strength not found in many other materials. They can withstand harsh weather environments and are able to control or balance pressure due to their high strength-to-weight ratio. Perforations also reduce the weight needed to support the building's frame.

4) Energy saving

By balancing light and ventilation, perforated metal allows architects to manage indoor heat build-up from the sun. By deflecting heat, HVAC systems require less energy output, providing a more consistent interior temperature. As a shielding element, perforated metal reduces the amount of room lighting required.

5) Environmentally friendly

As the ultimate green material for design and construction, perforated metal minimizes resource consumption due to its recyclability, reduces energy in use, promotes sustainability, and sparks innovation in innovative and creative design. Additionally, perforations reduce the amount of metal used, which reduces weight and fuel transportation costs to the construction site.

English

>

English

>

English

English

Russian

Russian

Spanish

Spanish

Tim Carter

My stainless steel plate order received today. That's exactly what I think. The product surface and quality are very good. We will recommend your company to others.