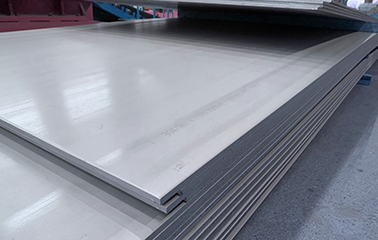

310 Stainless Steel Plate,310S Stainless Steel Sheet Product Details

| Product name |

Stainless Steel Sheet |

| Standard |

ASTM A240/240M , AISI, GB1220 , JIS, DIN17440, EN |

| Material |

201,304,304L, 304H, 316,316L, 316Ti, 321,309s, 310s, 904L, 410,410s, 409L, 420,420J,244,442,205,2507,2304,253MA, 254SMo, 317L, 347H, C-4, C-276, C-22, C-2000, Incoloy800, Incoloy825, Inconel600, Inconel625 |

| Surface |

Hot rolled (HR), Cold rolled (CR), 2B, 2BA, BA, NO 8,Brushed, Mirror 8K Mirror, Color Coating, Etched ,Anti-fingerprint,Water-Ripple,Perforated,Checkered |

| Technique |

Cold Drawn Hot Rolled Forged |

| Edge |

Mill edge,Slit edge |

| Thickness |

Cold rolled CR: 0.3-8mm;Hot rolled HR is 3-250mm |

| Application |

Automotive Trim and Molding;Builders Hardware, Fasteners ,and Furnace Parts;Interior Architectural Trim and Paneling;Kitchen Trim and Equipment;Zippers, Vaults, and Tubing;Tobacco Machinery, Television Cones, and Storage Vessels |

310 Stainless Steel Plate,310S stainless steel plate supplier | manufacturer | exporter

What is 310s stainless steel plate?

310S hot rolled stainless steel plate is similar to 310 stainless steel plate. The difference is that lower carbon content can reduce carbide precipitation and improve weldability. Compared with ordinary austenitic steel (such as SS 304), the nickel and chromium content of SS 310S steel plate has soared, and has similar corrosion resistance, higher oxidation resistance and higher room temperature effectiveness. 310S stainless steel plate is easy to manufacture.

Simple description of 310 Stainless Steel Plate and 310s stainless steel plates

The carbon content of hot-rolled 310s stainless steel plate is relatively high, 0.25%, while that of 310S stainless steel is low, 0.08%, with the same chemical composition.

Therefore, 310 stainless steel has high strength and hardness and poor corrosion resistance. 310S stainless steel has good corrosion resistance and slightly low strength. The price of 310S stainless steel plate is relatively high due to its low carbon content and difficult smelting.

The differences are summarized as follows:

1.The chemical composition is 310 stainless steel. The carbon content is 0.15%, and the requirement of 310S is 0.08%. In addition, he also requires that the MO content be less than or equal to 0.75%.

2. Surface hardness measured by strength. 310 stainless steel is larger than 310S stainless steel.

3. The corrosion resistance of 310S is greater than 310, because 310S added MO.

4. The high temperature resistance of 310S stainless steel is superior to 310 stainless steel under the same processing conditions.

More differences between hot-rolled and cold-rolled stainless steels

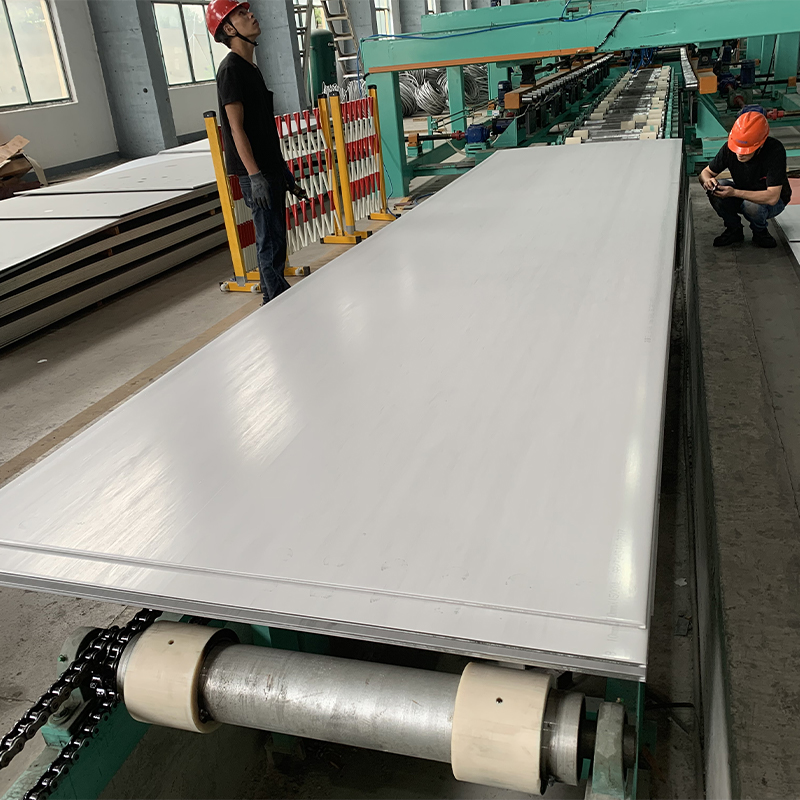

By definition, ingots or billets are difficult to deform and process at room temperature. Generally, they are heated to 1100 to 1250 ° C for rolling. This rolling process is called hot rolling. Most steels are hot rolled. But because the surface of steel is easy to produce scale at high temperature, the surface of hot rolled steel is rough and the size fluctuates greatly.

Therefore, it is required that the steel should have smooth surface, accurate size and good mechanical properties, and take hot rolled semi-finished products or finished products as raw materials, and then cold rolled. Rolling production.

|

Hot rolled stainless steel plate

Hot rolling, as the name implies, means that the temperature of the rolled piece is high, so the deformation resistance is small, and large deformation can be achieved. Taking the rolling of steel plate as an example, the thickness of continuous casting slab is generally about 230 mm. After rough rolling and finishing rolling, the final thickness is 1~20 mm.

|

|

|

|

|

|

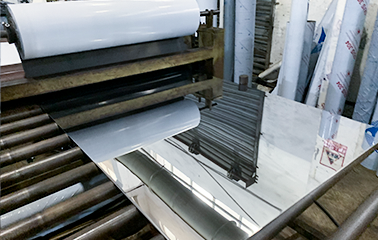

Cold rolled stainless steel plate

Cold rolling is generally understood as cold rolling. From the metallographic point of view, the boundary between cold rolling and hot rolling should be distinguished by recrystallization temperature. That is, the rolling below the recrystallization temperature is cold rolling, and the rolling above the recrystallization temperature is hot rolling. The recrystallization temperature of the steel is 450-600 ℃.

|

|

At the same time, due to the small width thickness ratio of the steel plate, the requirements for dimensional accuracy are relatively low, so it is not easy to have shape problems, and the convexity is mainly controlled.The requirements for microstructure are generally realized by controlling rolling and cooling, that is, controlling the microstructure and mechanical properties of strip steel by controlling the rolling temperature, finishing rolling temperature and finishing rolling crimp temperature.

Cold rolling, generally there is no heating process before rolling. However, due to the small thickness of the strip, the shape is easy to appear. In addition, cold rolling is the finished product. Therefore, in order to control the dimensional accuracy and surface quality of strip steel, many complex processes need to be adopted. Cold rolling production line is long, with many equipment and complex process.

With the improvement of users' requirements for strip size accuracy, shape and surface quality, the control model of cold rolling mill, L1 and L2 systems, and shape control methods are hot. Moreover, the temperature of roll and strip is one of the most important control indexes.

Cold rolled products and hot rolled products are different from the previous process and the next process. Hot rolled stainless steel products are raw materials of cold rolled products, and hot rolled steel coils are processed by pickling process. Rolling mill, rolling, is cold bending forming. It is mainly used to roll thick hot rolled plate into thin cold rolled plate through 3.0mm hot rolling mill, usually 0.3-0.7mm. The main principle of cold rolling coil is to use the extrusion principle to force deformation.

310 Stainless Steel Plate,310S Stainless Steel Sheet Mechanical Property

| 310 Mechanical properties |

| Tensile strength σ B (MPa) |

Conditional yield strength σ0.2 (MPa) |

Elongation δ5 (%) |

| ≥520 |

≥205 |

≥40 |

| SS 310s Mechanical Property Standard |

| Tensile strength σ B (MPa) |

Conditional yield strength σ0.2 (MPa) |

Elongation δ5 (%) |

≤624

|

≤314

|

≥32

|

310 and 310S stainless steel sheets are highly versatile and widely used in various industries due to their exceptional durability and resistance to high temperatures. These alloys are highly resistant to oxidation, corrosion, and high-temperature settings, making them ideal for use in harsh environments. They are commonly used in the production of furnace components, heat exchangers, and other high-temperature applications. 310 and 310S stainless steel sheets offer excellent weldability and machinability, making them ideal for use in fabrication processes. Additionally, these alloys are highly resistant to scaling and offer superior strength and toughness. Our company provides high-quality 310 and 310S stainless steel sheets to meet the needs of our customers in various industries.

310/310S stainless steel is an austenitic stainless steel with excellent high-temperature oxidation resistance. It is commonly used in applications where high temperature strength and resistance to thermal cycling are critical. The high chromium and nickel content in 310/310S stainless steel provides superior corrosion resistance in most environments.

310/310S stainless steel sheet is commonly used in a variety of industries, including heat treatment furnace components, kiln linings, combustion chambers, and other high-temperature applications. It is also used in the manufacturing of furnace components, such as radiant tubes, muffles, retorts, and conveyor systems.

English

>

English

>

English

English

Russian

Russian

Spanish

Spanish

Tim Carter

My stainless steel plate order received today. That's exactly what I think. The product surface and quality are very good. We will recommend your company to others.