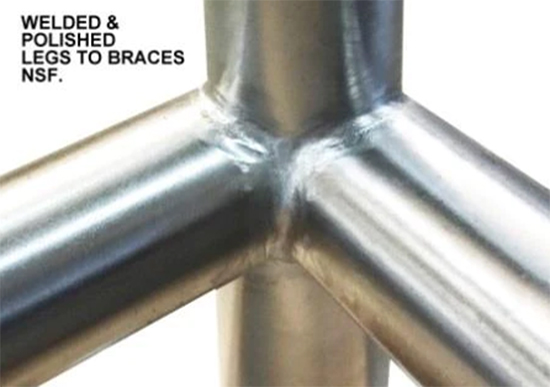

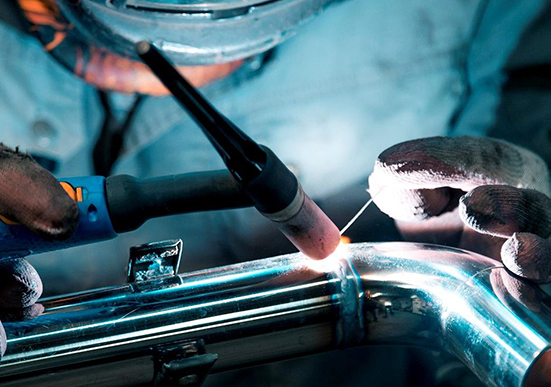

The Welding Process

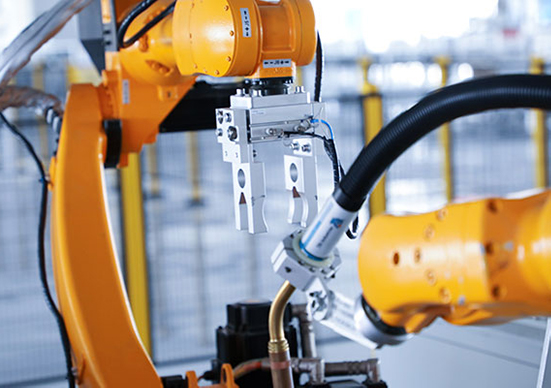

The welding process is generally mainly used on pipes, profiles and some special parts. Our welding processes mainly include argon arc welding, gas welding, submerged arc welding, manual welding, MIG/MAG welding, and TIG welding. Due to the large number of stainless steel grades, the weldability of different grades of stainless steel is different, according to the different needs of customers. Different welding methods can be used to protect the material to a certain extent.

Due to the particularity of the welding process, the inspection during the entire production process is also very important. The inspection before welding, the inspection during the welding process, the inspection of the finished product after the welding, and multiple inspections can also ensure the quality of the finished product. This is also one of our advantages.

Attention points of stainless steel profile Welding

1, normal stainless steel profiles of thermal conductivity and hot melt performance is very strong, line expansion coefficient is large, so the welding difficulty is also large, must use the corresponding welding way, to ensure good quality.

2. There will be residue splashing during welding construction, which will harm our eyes. Therefore, we must wear professional protective gear during construction, such as eye mask and helmet, which can ensure our personal safety.

3. When welding, the splashing scraps need to be treated well, because they are very easy to attach to the stainless steel profile on the outer layer, which will make the use of stainless steel time is reduced, so the welding needs to be coated with splashproof agent, which can effectively prevent the splashing of iron scraps.

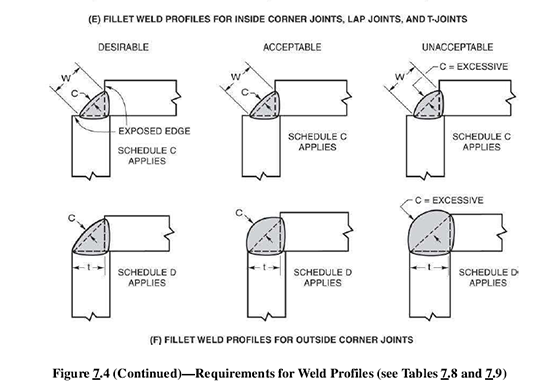

4. When linking, if the construction is not carried out in accordance with the operating base, it is very easy to cause defects in the outer layer, such as the damage of the protective film, the outer layer is uneven and so on. Therefore, it is necessary to lead the arc in the welding path and dissolve the traces in the weld line.

Why should the parameters be adjusted at any time when welding stainless steel?

The main reason why welders adjust welding parameters (voltage, current, arc length, induction coefficient and pulse width, etc.) at any time when welding stainless steel is mismatched welding material composition. Chemical composition is important, and differences in composition between batches can make a big difference in welding behavior. For example, poor wettability and slag removal, welding material diameter, surface cleanliness, pouring performance and spiral shape can affect the welding behavior in GMAW and FCAW.

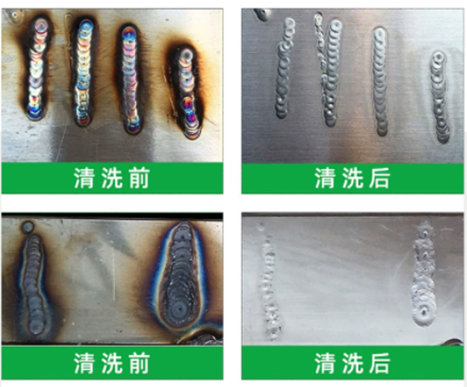

What is the appropriate pre-weld cleaning operation?

When welding with other materials, first use a chlorine-free solvent to remove oil, marks and dust. In addition, th to avoid being polluted by carbon steel and affect the corrosion resistance. Some companies store stainless steel and carbon steel separately to avoid cross-contamination. Use special grinding wheels and brushes for stainless steel when cleaning the area around the groove. Sometimes the joint needs to be cleaned a second time. Because the electrode compensation operation of stainless steel welding is more difficult than that of carbon steel welding, joint cleaning is very important.

The benefits of welding stainless steel

1. When it comes to welding, there are many benefits that come with stainless steel.

2. For one, it is a very strong and durable metal, which makes it ideal for welding projects that require a lot of strength.

3. Additionally, stainless steel is resistant to corrosion, so it can withstand being exposed to weld fumes and other chemicals without rusting or becoming damaged.

4. Finally, welding with stainless steel can give your projects a professional look and finish thanks to the shiny surface of the metal.

5. If you're looking for a strong, durable, and corrosion-resistant metal for your next welding project, consider using stainless steel.

Types of stainless steel welding

There are many types of stainless steel welding, each with its own set of advantages and disadvantages.

The most common type of stainless steel welding is arc welding. Arc welding is a versatile process that can be used to weld thin or thick metals, including stainless steel. It is also relatively easy to learn and can be done with relatively simple equipment. However, arc welding can produce harmful fumes, so proper ventilation is essential.

Another type of stainless steel welding is gas tungsten arc welding (GTAW). GTAW produces cleaner welds than arc welding and is often used for thinner metals. However, it requires more expensive equipment and is more difficult to learn than arc welding.

Still another type of stainless steel welding is plasma arc welding (PAW). PAW produces very high-quality welds but requires even more expensive equipment than GTAW.

Tips for welding stainless steel

There are a few things to keep in mind when welding stainless steel. First, it is important to use the correct type of filler metal. Stainless steel is typically joined with ER308, ER308L or ER316L filler metal. Second, it is important to clean the base metal prior to welding. Any contaminants on the surface of the stainless steel can cause problems with the weld. Third, when welding stainless steel it is important to use short, intermittent welds. This helps to prevent warping and distortion of the metal. Fourth, it is important to cool the weld area after welding. This helps to relieve stress on the metal and prevent cracking. Fifth, when finish welding it is important for the welder to remove any oxide from the surface of the weld.

How to control carbide precipitation in austenitic stainless steel?

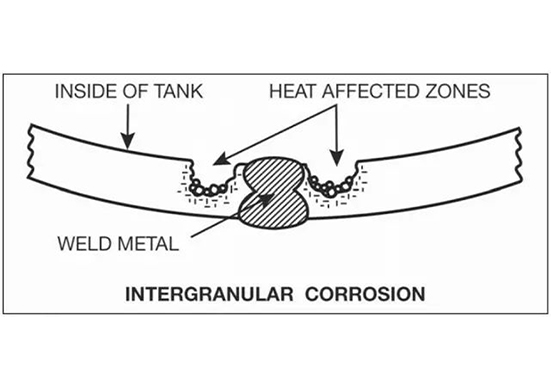

When the carbon content exceeds 0.02% at 800 to 1600 ° F, C diffuses and migrates to the austenite grain boundary where it reacts with Cr to form chromium carbides. If Cr is fixed in large quantities by element C, corrosion resistance will decrease. When exposed to corrosive conditions, intergranular corrosion occurs, causing grain boundaries to erode away.

English

>

English

>

Russian

Russian

Spanish

Spanish