Stainless Steel Laser Cutting

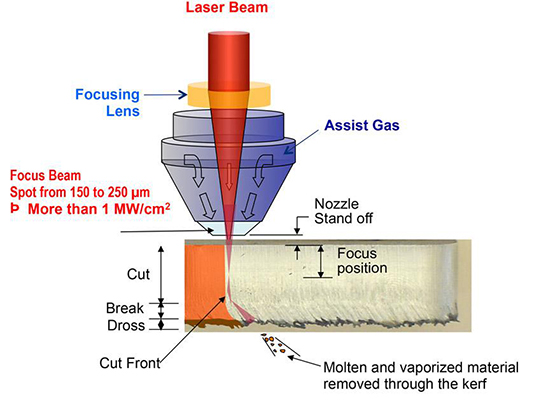

Stainless steel laser cutting uses the energy released when a laser beam hits the surface of the stainless steel plate to melt and evaporate the stainless steel. Due to the very concentrated energy, only a small amount of heat is transmitted to other parts of the port, resulting in little or no deformation. The laser can be used to cut billets of complex shapes very accurately, and the cut billets do not need to be further processed. . Common laser cutting processes are divided into vaporization cutting, melting cutting, oxidation melting cutting, and controlled fracture cutting.

Our laser cutting machines reduce operator dependence in the production process, resulting in increased accuracy, reduced human error, and further increased processing speed and efficiency. Laser processing has obvious advantages as a whole. Whether it is accuracy, speed or cost, laser processing has obvious advantages, and it is easier than other processing methods to change graphics. It is an indispensable processing method in the production process.

Stainless Steel Laser Cutting technology processing range

Laser processing technology is an advanced manufacturing technology, it has the advantages of precision manufacturing, flexible cutting, profile-shaped processing, one-time forming, fast speed, high efficiency. And laser cutting, welding is a part of laser processing field. Laser cutting is an important application technology in the laser processing industry, laser cutting without burr, wrinkle, high precision, better than plasma cutting. For the mechanical and electrical manufacturing industry, the modern laser cutting system of the microcomputer program can facilitate the cutting of different shapes and sizes of the workpiece (workpiece drawings can also be modified), it is often preferred over the punching, molding process. Processing scope: 1, stainless steel, carbon steel, iron plate and other plates, square pipe, round pipe, Angle channel steel profile laser cutting. 2, mechanical equipment and accessories. 3, hardware tools, molds, hardware accessories, auto parts. 4, stainless steel, iron products. Applicable materials: stainless steel, carbon steel, alloy steel, aluminum plate, iron plate and other metal plate and pipe.

Effect of laser frequency adjustment and pulse duty cycle on cutting quality

The influence of frequency change on the cutting of stainless steel thick plate:

The frequency decreases from 500-100Hz, the cutting section effect becomes delicate, and the stratification is gradually improved. When the frequency is set to 100Hz, it can not be cut and anti-blue light. Through the change of frequency, find out the best frequency range. In order to ensure the best cutting section, it is necessary to ensure the perfect match between pulse frequency and single pulse energy.

Influence of pulse duty ratio change on stainless steel thick plate cutting:

The pulse duty ratio of 45% is the critical value. As the duty ratio continues to decrease, the trace of not cutting through appears on the lower surface, and the duty ratio increases to 60%. The section becomes rough, the stratification is obvious, and the cutting surface becomes yellow.

The process of laser cutting stainless steel

Laser cutting is a process that uses a laser to cut materials. The process is mainly used for cutting metals such as stainless steel. The process can also be used to cut other materials, such as wood and plastic.

The laser cutting process works by using a high-powered laser to heat the material being cut. The material is then vaporized or burned away by the laser. The process is very precise and can be used to create intricate designs.

Laser cutting is a popular choice for many manufacturing applications because it is fast, accurate, and produces little waste material. The process can be automated, which makes it ideal for large-scale production runs.

The benefits of laser cutting stainless steel

Laser cutting has become extremely popular in recent years for a number of reasons. One of the most popular materials to use with laser cutting is stainless steel. Stainless steel is a durable, strong material that can withstand high temperatures and is very easy to clean. Laser cutting stainless steel is a precise and efficient way to cut through this tough material.

There are a number of benefits to using laser cutting for stainless steel. First, it is a very precise method of cutting. This means that you can achieve very intricate designs and patterns with ease. Second, laser cutting is very fast. This can be a huge time saver when you are working on large projects. Finally, laser cutting produces very little waste. This can save you money in the long run by reducing the amount of material you need to purchase.

The challenges of laser cutting stainless steel

When it comes to cutting stainless steel with a laser, there are a few challenges that need to be taken into account. The first challenge is the reflectivity of stainless steel. This can cause the laser beam to bounce off the surface of the metal, making it difficult to get a clean cut. Additionally, stainless steel is a very hard material, so it can be difficult to cut through with a laser. Finally, because stainless steel is such a good conductor of heat, it can be difficult to control the amount of heat that is generated when cutting with a laser.

Why laser cutting is the best option for stainless steel

If you're looking for the best way to cut stainless steel, look no further than laser cutting. Laser cutting is a process that uses a high-powered laser to cut through material. The laser beam is focused on a small area of the material, which heats up and vaporizes the material. This process is extremely precise and can be used to cut through very thick materials.

There are many reasons why laser cutting is the best option for stainless steel. First, it's extremely precise and can produce very intricate designs. Second, it's fast and efficient, which means you can get your project done quickly. And third, it produces very little waste.

If you're looking for a quick, efficient, and precise way to cut stainless steel, then laser cutting is the best option for you.

English

>

English

>

Russian

Russian

Spanish

Spanish