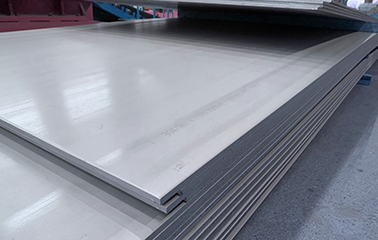

The Stainless Steel Flattening Process

The stainless steel flattening process is a processing method for cutting steel coils into flat plates. The steel plate is adjusted to a straight state through the steel plate uncoiler and leveling equipment to meet the production and use of steel materials that generally have good elastic recovery ability. flat effect. At present, the common leveling machines on the market can be roughly divided into three categories according to their processing capabilities: medium plate leveling, thin plate leveling, and precision small leveling, which can basically meet various processing requirements.

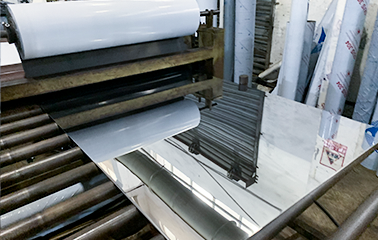

The stainless steel slitting process is to divide a stainless steel strip of a certain width into one or several stainless steel coils of a specified width as required. Compared with Kaiping, slitting is a relatively technical processing method. At the same time, the size of the strip is generally more stringent. In addition, in the slitting operation, the choice of the blade, the choice of the blade collar, the horizontal clearance of the blade and the overlap of the blade are all very important, which are related to the precision and quality of the cut product. Our company can provide customers with advanced equipment and professional services, which can reduce losses during the production process and provide customers with the best quality products.

What is decoiling and slitting?

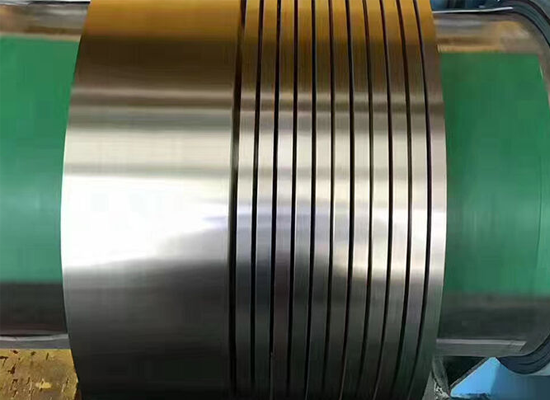

Decoiling and slitting are two important processes in the manufacture of metal products. Decoiling involves unwinding a coil of metal so that it can be fed into a machine for further processing. Slitting is the process of cutting the metal coil into narrower strips that are then used in various applications such as welding or forming.

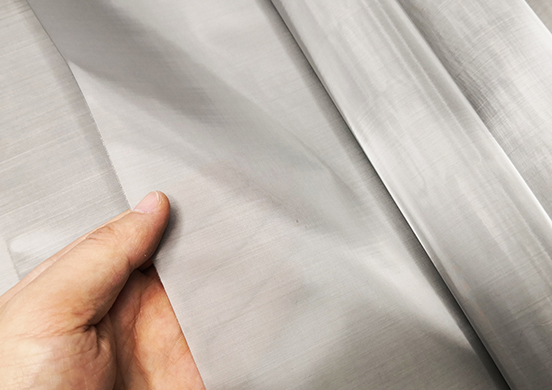

These processes are essential for ensuring that metal products meet the specifications required for their intended use. Decoiling and slitting help to ensure that the metal is of the correct thickness and width, and that it has a smooth surface finish.

The process of decoiling and slitting stainless steel

The process of decoiling and slitting stainless steel is a two-step process that involves first decoiling the steel, and then slitting it to the desired width.

Decoiling is the process of unrolling the steel coil so that it can be fed through the slitting machine. The coil is placed on a mandrel, which unrolls the steel as it feeds it through the machine.

Slitting is the process of cutting the steel into strips of the desired width. The slitting machine has a series of knives that cut through the steel as it feeds through the machine. The width of the slit can be adjusted by moving the knives closer together or further apart.

After the steel has been decoiled and slit, it is then ready to be used in a variety of applications.

The benefits of decoiling and slitting stainless steel

There are many benefits of decoiling and slitting stainless steel. The first benefit is that it increases the strength of the metal. This is because when the metal is in one continuous piece, it is less likely to break or bend. The second benefit is that it makes the metal more malleable. This means that it can be shaped into different forms more easily. The third benefit is that it makes the metal easier to work with. This is because when the metal is in smaller pieces, it can be cut and worked with more easily.

The challenges of decoiling and slitting stainless steel

coiling and slitting stainless steel can be significant. The process of decoiling—which is the straightening and unwinding of coils of metal—can be difficult with this type of material. Slitting is the cutting of sheets into strips, and this too can pose problems due to the hardness of stainless steel. Though these challenges exist, there are ways to overcome them in order to create the desired product.

One challenge that is often faced when decoiling and slitting stainless steel is its hardness. This quality makes the metal difficult to straighten and cut, but there are ways to overcome these obstacles. One method is by using a higher power laser, which will heat up the material enough to make it easier to work with.

Flat and slitting of stainless steel coil

Some quality problems will be caused by improper operation or some unexpected factors in the slitting process. Common surface bump points, scratch lines, creases and so on. Excluding the problem of raw materials, the clamping roll, measuring wheel and other parts that have direct contact with the stainless steel coil may cause the above defects.

Generally, the size requirements of the strip are relatively strict, and the deviation or inaccurate data of the row tool in the process of processing will cause the product size deviation. Incorrect clearance or pressure during tool row will cause out-of-tolerance shear burr, which should be paid special attention to when welding pipe materials.

Winding due to tension and other reasons will cause uneven winding or drum deformation, which will indirectly give the product agent defects. Generally speaking, stainless steel coils of 0.4mm and below thickness are more likely to appear in the above quality conditions.

Stainless Steel flat and rolling mill difference

1. The measurement of deformation is different

In the rolling process, the technological parameter to measure the deformation of strip is the reduction rate, while in the flattening process, the technological parameter to measure the deformation of strip is the elongation. The deformation directions are different: the reduction rate reflects the deformation in the direction of the strip thickness, while the elongation reflects the change in the strip length. The measurement methods are different: the reduction rate can reflect the deformation of the strip at any time in the rolling process, while the elongation reflects the deformation of the strip in some specific time interval in the process of manufacturing, so the reduction rate reflects the measurement value of continuity, and the elongation reflects the measurement value of discontinuity.

2. The nature of deformation is different

Due to the small amount of deformation in the flattening process, it is only surface deformation and does not change the nominal thickness of the strip. And the rolling process requires as much deformation as possible, it makes the entire thickness of the strip cut deformation, change the thickness of the strip to reach the required thickness of the product.

3. Differences in process control

The target of rolling process control is qualified strip thickness, while the target of leveling process control is certain elongation.

4. Different influences on strip properties

The tensile strength and yield strength of the rolled strip increased obviously, and the plasticity index decreased obviously. After leveling, the yield strength of the strip decreases, the plasticity index changes little, and the tensile strength does not rise much.

English

>

English

>

Russian

Russian

Spanish

Spanish