Color-plated Stainless Steel

As a hot-selling product on the market, color-plated stainless steel is also one of our main products. Color-plated stainless steel has the luster and strength unique to metal, as well as bright colors, and is very popular as architectural decoration. Our coloring process is mainly divided into electroplating, water plating, fluorocarbon paint and spray paint. Stainless steel colored by these coloring processes not only maintains the physical, chemical and mechanical properties of primary color stainless steel, but also has stronger corrosion resistance than primary color stainless steel. widely used.

In addition, our company also produces color-coated mirror panels, color-coated wire drawing panels, color-coated etched panels, etc. for customers to choose.

Three features of color-plated stainless steel

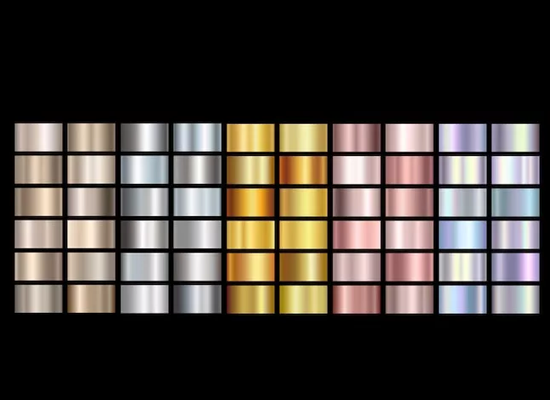

1. Rich colors, titanium gold, gold, black gold, rose gold, sapphire blue, champagne gold, bronze, emerald green and so on;

2. There are various surface patterns, such as mirror, drawing, matte, and grain, etching, embossing and so on;

3. Color stainless steel not only maintains its own physical, chemical and mechanical properties, but also has stronger corrosion resistance and salt spray corrosion resistance than the primary color stainless steel. The color surface is durable, resistant to high temperature, and can be recycled.

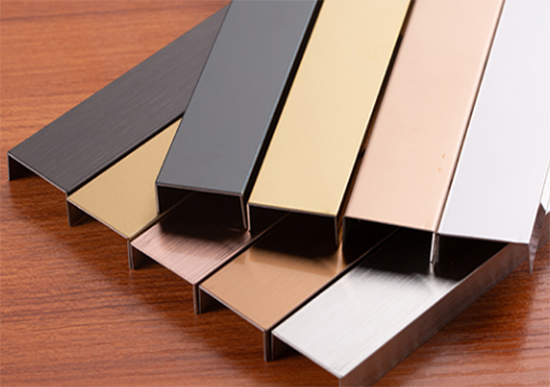

Colored stainless steel line

Stainless steel lines, with scratch resistance and fade resistance, waterproof and anti-corrosion, size can be customized, environmental protection and easy to clean, beautiful no marks, let a person's eyes bright; Its color is very rich, such as black titanium, titanium, champagne gold, rose gold, tawny, bronze, bronze and so on. The color surface is durable, and the color will vary with the light Angle. It can enhance the sense of balance and depth of the space. The horizontal width is far and the vertical height is high, creating a wonderful delicacy for the space.

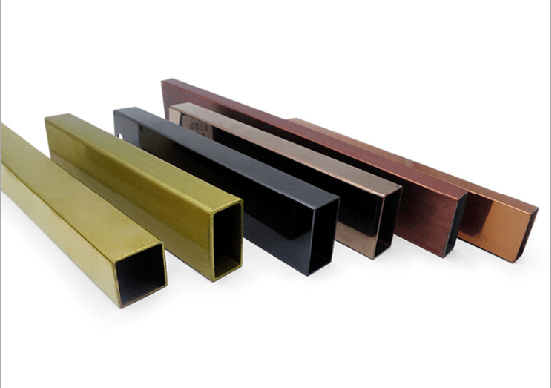

Colored stainless steel tube

Colorful stainless steel decorative pipe varieties are rich: round pipe, square pipe, horseshoe pipe, bright pipe, ingot pattern pipe, Xiangyun pattern pipe, back pattern pipe and so on; Coloring process: spray painting, spraying, electroplating, vacuum plating and so on; The color is gorgeous, dazzling: titanium, rose gold, bronze, brass.

Stainless steel color tube is a kind of environmental protection decorative material, does not contain harmful substances, no radiation, safe fire. The material itself is not only free of chemical hazards, and the product can be recycled and reused, advocating the environmental protection of the century, green environmental protection is everyone's responsibility.

Colored stainless steel trim panel

Color stainless steel shows great artistic charm in the field of architectural design. Under the premise of maintaining the inherent luster of metal, it appears full, round, soft and gorgeous. It perfectly integrates its excellent physical properties with excellent artistic expression, and reflects excellent comprehensive performance.

Applied in decoration has the advantages of optical properties, corrosion resistance, heat resistance, anti-wear and anti-scratching properties, processing formability, surface resistance to Sassafras washing and so on;

Color stainless steel decorative plate service life generally can be more than ten years, and under normal circumstances do not fade and rust.

The benefits of color coating stainless steel

Stainless steel is a popular material for appliances and cookware because it doesn't rust, stain or corrode easily. Another advantage of stainless steel is that it's easy to clean. However, one downside to stainless steel is that it can show fingerprints and smudges easily.

One solution to this problem is color coating stainless steel. Color coating adds a layer of protection that helps to resist fingerprints and smudges. It also can add a pop of color to your kitchen décor. Some companies even offer custom colors to match your home's style.

In addition to its aesthetic advantages, color coating also helps to extend the life of your stainless steel appliances and cookware. The color coat acts as a barrier against scratches, nicks and other wear and tear. This can help your items last longer and stay looking new for years to come.

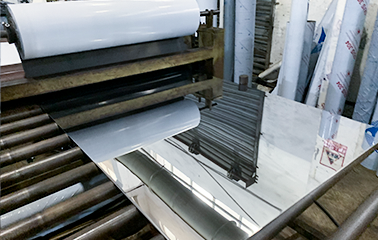

The process of color coating stainless steel

1. The process of color coating stainless steel is a multi-step process that begins with the preparation of the steel surface. The surface is cleaned and prepped before a base coat is applied. Once the base coat has been applied, a topcoat is then applied.

2. The topcoat can be applied using one of two methods: wet or dry. Wet painting involves applying the paint to the metal surface while it is still wet from the base coat. Dry painting, on the other hand, requires the paint to be dry before it is applied to the metal surface.

3. After the topcoat has been applied, it needs to be cured in order for the paint to set properly. Curing can be done either by air drying or by baking in an oven. Once the paint has been cured, it will be resistant to chipping and fading.

The different colors available for color coating stainless steel

stainless steel is a popular choice for many homeowners and businesses due to its durability and low maintenance cost. While the initial investment for stainless steel may be higher than other materials, the long-term savings are often worth the extra expense. One of the benefits of stainless steel is that it can be ordered in a wide range of colors. The different colors available for color coating stainless steel can help to create a unique look for your home or business.

There are a few different ways that manufacturers can create colors on stainless steel. One common method is through anodizing. This process creates a thin oxide layer on the surface of the metal which can then be dyed in a wide range of colors. Another popular method is PVD (physical vapor deposition) coating.

The advantages of color coating stainless steel over other methods

There are many advantages of color coating stainless steel over other methods, including its aesthetics, durability, and low maintenance.

Color coating provides a protective layer that helps to prevent corrosion and weathering. It is also resistant to staining and fingerprints.

Color coating stainless steel is an environmentally friendly option as it does not use toxic chemicals or paints. It is also a more sustainable option as the coating can last for many years.

Overall, color coating stainless steel is a great option for those looking for a durable and low-maintenance finish.

Why choose color coating stainless steel?

There are many reasons to choose color coating stainless steel for your next project. Here are just a few of the reasons why:

1. Color coating stainless steel is highly durable and resistant to corrosion and scratching.

2. The finish can be customized to any color or design you desire, giving your project a unique look.

3. Color coating stainless steel is easy to maintain and clean, making it ideal for high-use areas.

4. The coating provides an extra layer of protection against the elements, helping to extend the life of your project.

5. Color coating stainless steel is an environmentally friendly option, as it does not release harmful toxins into the air during manufacturing or use.

English

>

English

>

Russian

Russian

Spanish

Spanish