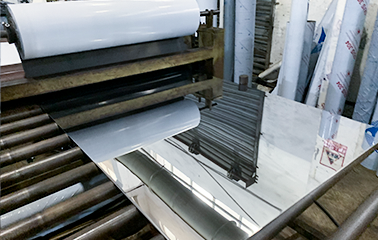

The Stainless Steel Wire Drawing Process

The stainless steel wire drawing process uses the reciprocating motion of the wire drawing cloth, and the friction back and forth on the surface of the product is a method to improve the surface finish of the product, and the surface texture is linear. The common methods and effects of stainless steel wire drawing process are mainly divided into straight wire pattern, nylon pattern and snow pattern. Stainless steel wire drawing is very particular about procedures and processes. Generally, the wire drawing machine is used to repair and restore the scratched position and weld seam of the product, and finally achieve the overall artistic effect of wire drawing. The common surface is No.4, which is characterized by polishing and finishing with abrasive materials with a particle size of 150~180.

Our wire drawing work is carried out automatically by the machine, so the depth and thickness of the wire can be better grasped, and the speed is faster. Professional wire drawing equipment not only saves costs for customers, but also improves production efficiency.

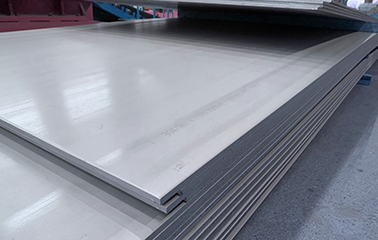

Stainless Steel Wire Drawing plate production and processing

Wire drawing is just a process and has no relation to the type of stainless steel. This means that brushed metal sheets can be made from ordinary steel sheet materials. The coated plate can also be colored by electroplating or water plating.

In decorative design, different colors of the drawing board can create different atmosphere and style. Commonly used colors are stainless steel wire drawing titanium metal plate, black titanium metal wire drawing plate, Champagne gold metal wire drawing plate, rose gold metal wire drawing plate, blue and white porcelain wire drawing plate. Brushed sheet metal is scratch resistant and corrosion resistant. At the same time, the surface can be anti-fingerprint treatment, so as to avoid fingerprint pollution.

Therefore, items that are often attacked by fingerprints, such as elevator railings, stair railings, doors and Windows. Brushed metal sheets and brushed stainless steel tubes are often used as decorative materials.

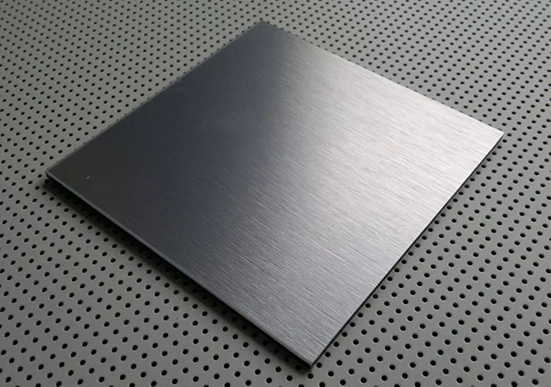

Brushed Stainless Steel plate

The drawing process will lose the thickness of the stainless steel plate to a certain extent, generally in 0.1~0.2mm. In addition, because the human body, especially the palm, has a relatively strong oil and sweat secretion, brushed stainless steel plate often touch with the hand will leave a more obvious fingerprint, the need to scrub regularly.

At present, the drawing stainless steel plate can be divided into: oil grinding wire drawing, dry grinding wire drawing, water grinding wire drawing, among which the oil grinding wire drawing effect is the most ideal, and the appearance and other aspects are satisfactory!

Brushed stainless steel plate is a conventional plate on the market at present, that is, a straight line is covered with the whole stainless steel plate. And the 8K mirror plate is like a glass mirror effect. Brushed stainless steel plate is the effect of grinding out the sand belt, relatively simple, and fast.

Brushed Stainless Steel sculpture

Drawing process, also known as matte, usually in the stainless steel surface mechanical friction processing method to get the surface state of straight lines, stainless steel drawing effect has straight silk, snow pattern, nylon pattern three.

The surface of the brushed stainless steel sculpture is matte, and there is a trace of texture on it carefully. It is wear-resistant and more classy than the general bright stainless steel. The drawing process will reduce the thickness of the stainless steel plate to a certain extent, generally within 0.1~0.2mm.

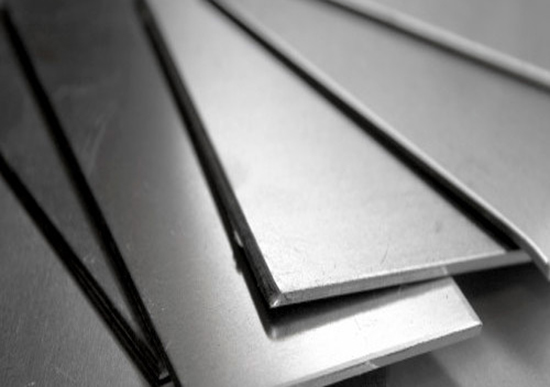

Advantages: why choose brushed stainless steel?

An increasing number of homeowners are choosing brushed stainless steel for their appliances, countertops, and fixtures. There are many advantages to choosing brushed stainless steel over other materials.

Brushed stainless steel is more durable than other materials. It is scratch resistant and won't show fingerprints or smudges. Stainless steel is also easy to clean. Just wipe it down with a damp cloth and it will look like new again.

Another advantage of brushed stainless steel is that it is low maintenance. Unlike other materials, you don't have to worry about sealing or waxing it to keep it looking new. Stainless steel will also never rust or tarnish.

If you're looking for a material that is both beautiful and practical, then brushed stainless steel is the perfect choice for you.

How it's made: the process of creating brushed stainless steel

How it's made: the process of creating brushed stainless steel is a complicated and time-consuming process. It begins with the selection of the raw materials. The stainless steel must be of the highest quality to create a product that will last for years. Once the stainless steel is selected, it is cut into thin strips. These strips are then passed through a series of rollers that gradually make them thinner.

After the rolling process, the strips are annealed, or heated to high temperatures and then cooled slowly. This helps to make the metal more pliable and less likely to crack during the next step, which is known as cold working. During cold working, the strips are passed through a series of rollers that compress them and give them their final shape.

Applications: where brushed stainless steel is used

Brushed stainless steel is used in many applications where a consistent, low-maintenance finish is required. Some of these applications include:

-Architectural panels and facades

-Interior and exterior cladding

-Furniture and joinery

-Handrails and balustrades

In each of these applications, brushed stainless steel provides a modern, sleek look that is easy to maintain. As well as being visually appealing, brushed stainless steel is also highly durable, making it an ideal choice for high traffic areas.

Maintenance: how to care for brushed stainless steel

If you have brushed stainless steel in your home, it's important to know how to properly care for it. Here are some tips:

1. Use a soft cloth or sponge when cleaning. Avoid using anything abrasive, which can scratch the surface.

2. When cleaning, use a mild soap and water solution. Avoid using harsh chemicals, which can damage the finish.

3. Dry the surface immediately after cleaning to prevent water spots from forming.

4. If there are stubborn stains, you can use a commercial stainless steel cleaner or white vinegar diluted with water. Apply with a soft cloth and rub in a circular motion until the stain is removed. Rinse well and dry afterwards.

5. To polish the finish, use a commercial stainless steel polish or a mixture of equal parts olive oil and lemon juice applied with a soft cloth.

English

>

English

>

Russian

Russian

Spanish

Spanish