The Stainless Steel Bending And Forming Services

Stainless steel bending and forming services are a great way to get the most out of your stainless steel products. By using these services, you can ensure that your products will have the right shape and size for your needs. There are many benefits to using these services, and we will discuss some of them below.

One of the main benefits of using stainless steel bending and forming services is that you can save time and money. If you were to try to bend or form stainless steel yourself, it would take a lot longer than if you let a professional do it. In addition, if you do not have the right tools or experience, you could end up damaging your product. By using professional services, you can avoid all of these potential problems.

Another benefit of using stainless steel bending and forming services is that you can get a better finish on your product.

What is the Progress Of Stainless Steel Bending?

The process of stainless steel bending is a highly efficient way to produce large numbers of parts with a very high degree of accuracy. The process is also very versatile, allowing for the creation of parts with a wide variety of shapes and sizes.

The first step in the stainless steel bending process is to create a die, or negative impression, of the desired shape. This die is then used to press the metal into the desired shape. The process is extremely accurate, and can produce parts that are virtually identical to the die.

The second step in the process is to heat the metal to its melting point. This allows the metal to be easily formed into the desired shape. Once heated, the metal is then cooled rapidly, which gives it its final shape.

What is the Stainless Steel Bending Strength Of Materials?

When it comes to finding out the stainless steel bending strength of materials, there are a few tests that can be done in order to determine this. The first is the Reverse Bend Test, which is where a sample of the material is bent backwards and forwards until it breaks. The second test is the Ring Tension Test, which is where a ring made from the material is placed under tension until it snaps. Finally, there is the Double Shear Test, which involves cutting two specimens of the material in half and then measuring how much force was required to do so. By conducting these tests, engineers can get a good idea of just how strong stainless steel really is.

Common applications for bent stainless steel

Bent stainless steel is a versatile material that can be used in a variety of applications. Here are some of the most common uses for bent stainless steel:

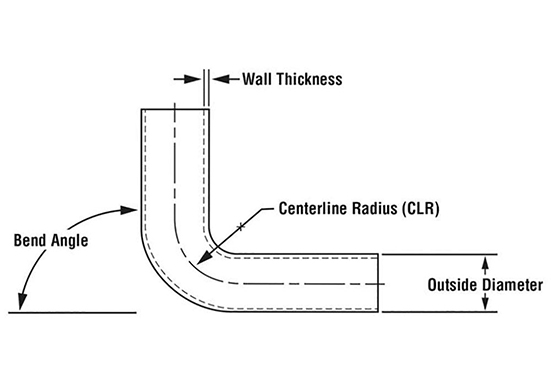

1. Piping: Bent stainless steel is often used to create piping for various applications. This includes everything from plumbing to automotive exhaust systems.

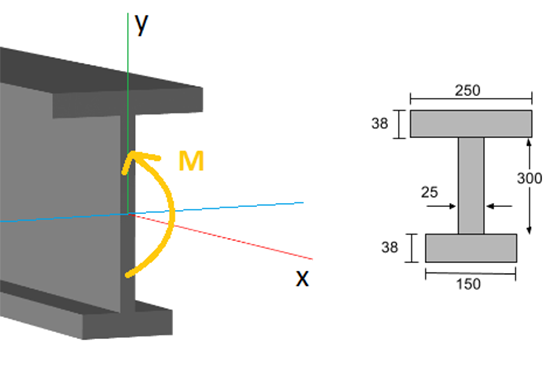

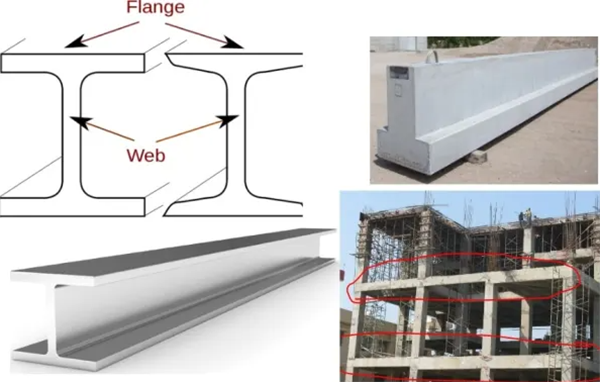

2. Structural support: Bent stainless steel can be used to provide support for various structures. This includes both buildings and bridges.

3. Fencing: Another common use for bent stainless steel is fencing. This material is often used to create both ornamental and functional fences.

What are the types of stainless steel bending processes?

When it comes to stainless steel bending, there are several different processes that can be used. Each process has its own advantages and disadvantages, so it’s important to choose the right one for the job at hand.

The three most common types of stainless steel bending processes are cold forming, hot forming, and press brake forming.

Cold forming is a process that uses high pressure to force the material into the desired shape. This method is typically used for small parts or when intricate shapes are required.

Hot forming is a process that uses heat to soften the material before it’s formed into the desired shape. This method is typically used for larger parts or when a more precise finish is needed.

Press brake forming is a process that uses a die to form the material into the desired shape.

The benefits of bent stainless steel

If you are looking for a more durable and long lasting option for your stainless steel needs, then bent stainless steel is the way to go. This type of steel is known for its resistance to corrosion and its ability to withstand high temperatures, making it an ideal choice for a variety of applications.

Bent stainless steel can be used in a wide range of industries, from food and beverage processing to medical and aerospace. It is also a popular choice for architectural applications due to its aesthetic appeal. In addition to its durability and strength, bent stainless steel has a number of other advantages that make it an attractive option for many different projects.

For one, bent stainless steel is easier to work with than traditional straight stainless steel. This makes it an ideal choice for fabricators and welders who are looking for a quicker and easier way to complete their projects.

What machines are used for bending?

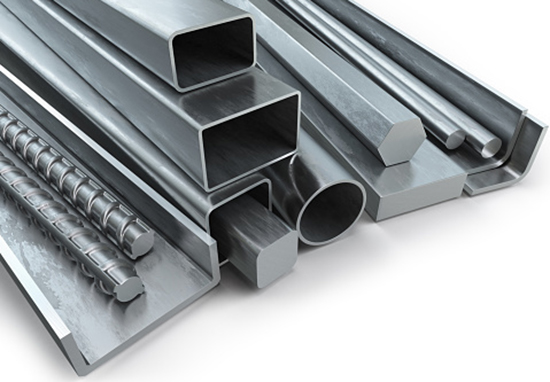

Different types of machines are used for different metal bending processes. They are Brake Press/Metal Sheet Bending Machine, Metal Shearing Machines, Sheet Metal Folding Machine, Section Bending Machine/Profile Bending Machine, Plate Rolling Machine, Pipe/Tube Bending Machine, Stretch Forming Machine, Roll Forming Machine, and Punch Press.

English

>

English

>

Russian

Russian

Spanish

Spanish