Common applications of stainless steel welded pipes in various industries

Stainless steel welded pipes are widely used in various industries due to their excellent corrosion resistance, strength, and durability. They are made by forming a flat strip of stainless steel into a tubular shape and then welding the edges together to form a seam. This article will explore the common applications of stainless steel welded pipes in various industries, the types of stainless steel welded pipes, how to select the right stainless steel welded pipe for your project, and how to test the strength and durability of stainless steel welded pipes.

Types of Stainless Steel Welded Pipes and Their Characteristics

There are several types of stainless steel welded pipes available on the market, each with its unique characteristics. The most common types of stainless steel welded pipes are:

Austenitic Stainless Steel Welded Pipes

Austenitic stainless steel welded pipes are the most widely used type of stainless steel welded pipes. They are highly corrosion-resistant and have excellent mechanical properties, making them suitable for use in various industries such as food processing, chemical, and pharmaceutical. They are also non-magnetic and have good weldability.

Ferritic Stainless Steel Welded Pipes

Ferritic stainless steel welded pipes are another type of stainless steel welded pipes. They have a higher chromium content than austenitic stainless steel welded pipes, making them more resistant to corrosion in certain environments. They are also magnetic and have good formability.

Duplex Stainless Steel Welded Pipes

Duplex stainless steel welded pipes are a combination of austenitic and ferritic stainless steel welded pipes. They have excellent corrosion resistance and high strength, making them suitable for use in harsh environments such as offshore oil and gas platforms.

Martensitic Stainless Steel Welded Pipes

Martensitic stainless steel welded pipes have a higher carbon content than other types of stainless steel welded pipes. They are highly resistant to corrosion and have good strength, making them suitable for use in applications such as knives, surgical instruments, and dental tools.

Common Applications of Stainless Steel Welded Pipes in Various Industries

Stainless steel welded pipes are used in various industries due to their excellent properties. Some of the common applications of stainless steel welded pipes are:

Food Processing Industry

The food processing industry requires materials that are hygienic and easy to clean. Stainless steel welded pipes are suitable for use in this industry due to their excellent corrosion resistance and non-toxic properties. They are used to transport food products, water, and other liquids.

Chemical Industry

The chemical industry requires materials that are resistant to corrosion and chemical reactions. Stainless steel welded pipes are suitable for use in this industry due to their excellent corrosion resistance and ability to withstand high temperatures. They are used to transport chemicals, gases, and other materials.

Oil and Gas Industry

The oil and gas industry requires materials that are resistant to corrosion and able to withstand harsh environments. Stainless steel welded pipes are suitable for use in this industry due to their excellent corrosion resistance and high strength. They are used in offshore oil and gas platforms, pipelines, and other applications.

Pharmaceutical Industry

The pharmaceutical industry requires materials that are hygienic and easy to clean. Stainless steel welded pipes are suitable for use in this industry due to their excellent corrosion resistance and non-toxic properties. They are used to transport pharmaceutical products, water, and other liquids.

Automotive Industry

The automotive industry requires materials that are strong and able to withstand high temperatures. Stainless steel welded pipes are suitable for use in this industry due to their high strength and ability to withstand high temperatures. They are used in exhaust systems, fuel lines, and other applications.

How to Select the Right Stainless Steel Welded Pipe for Your Project

Selecting the right stainless steel welded pipe for your project is crucial to ensure its success. Some factors to consider when selecting a stainless steel welded pipe are:

Corrosion Resistance

The corrosion resistance of the stainless steel welded pipe is an essential factor to consider when selecting a pipe. The level of corrosion resistance required will depend on the environment in which the pipe will be used.

Mechanical Properties

The mechanical properties of the stainless steel welded pipe are also crucial to consider when selecting a pipe. The level of strength and toughness required will depend on the application of the pipe.

Weldability

The weldability of the stainless steel welded pipe is also an essential factor to consider when selecting a pipe. The ease of welding will depend on the type of stainless steel welded pipe selected.

Cost

The cost of the stainless steel welded pipe is also an important factor to consider when selecting a pipe. The cost will depend on the type of stainless steel welded pipe selected and its size.

How to Test the Strength and Durability of Stainless Steel Welded Pipes

Testing the strength and durability of stainless steel welded pipes is crucial to ensure their reliability and safety. Some methods to test the strength and durability of stainless steel welded pipes are:

Tensile Testing

Tensile testing is a method used to determine the strength of a material. This test involves applying a tensile force to the stainless steel welded pipe until it breaks.

Impact Testing

Impact testing is a method used to determine the toughness of a material. This test involves striking the stainless steel welded pipe with a hammer or other object and measuring the amount of energy absorbed by the material.

Hardness Testing

Hardness testing is a method used to determine the resistance of a material to indentation. This test involves measuring the depth of an indentation made by a standard indenter on the surface of the stainless steel welded pipe.

Corrosion Testing

Corrosion testing is a method used to determine the resistance of a material to corrosion. This test involves exposing the stainless steel welded pipe to a corrosive environment and measuring the rate of corrosion.

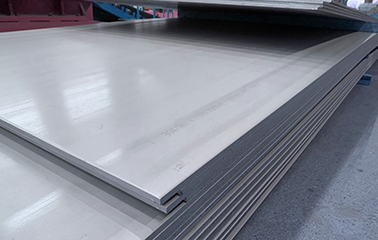

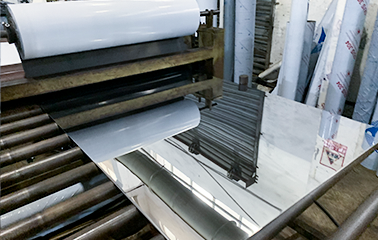

China Stainless Steel Flex Pipes Manufacturer

Luoyang Huaci Metal Product Co.,Ltd was established in 1999, located in Henan province, an important comprehensive transportation hub in our country . We are a manufacturer and wholesaler of independent import and export rights. The main products of our company steel steel are stainless ,stainless steel coil,stainless steel round tube,stainless steel square tube,stainless steel round bar,stainless steel flat bar,stainless steel channel,stainless steel angle bar and stainless steel sheet metal fabrication.If you are looking for a professional Stainless steel pipe Manufacturer in China, please contact us now, we provide quality products and first-class services.

English

>

English

>

Russian

Russian

Spanish

Spanish